DWS System logistics warehouse sorting

Product Description:

Applications:

Product Description:

DWS System could help clients solve one-time weighing, volume measurement, barcode recognition, manual input, camera archiving, and other five basic functions.

Applications:

Widely used in Logistics, Warehouses, E-commerce, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plants, Food and beverage Factory, Farms, Retail, Food Shops, and Express industries.

NEWS & EVENTS

- Tel: 0086 173 1754 7809

- Email: info@smartconvey.com

- Mon-Fri 9:00AM - 7:00PM

Advantages:

- DWS can work with a high-speed Conveyor System.

- DWS could achieve high efficiency to a max of 3600 parcels/hour.

- The data can be directly used in the management system.

- Support multiple and customized data transfer modes.

- The modular design concept provides a variety of application methods.

| Basic Dimensions | |

| Model No. | Dimension(L*W*H) |

| SC-400DWS | 1.0m/1.2m/1.4mx600mmx800mm |

| SC-500DWS | 1.0m/1.2m/1.4mx700mmx800mm |

| SC-600DWS | 1.0m/1.2m/1.4mx800mmx800mm |

| SC-700DWS | 1.0m/1.2m/1.4mx900mmx800mm |

| SC-800DWS | 1.0m/1.2m/1.4mx1000mmx800mm |

| SC-900DWS | 1.0m/1.2m/1.4mx1100mmx800mm |

| SC-1000DWS | 1.0m/1.2m/1.4mx1200mmx800mm |

| Remark: Other dimensions could be customized | |

| Basic Information | |

| Capability | Up to 3600 pieces per hour |

| Conveying Speed | 72~90 m/min(Adjustable) |

| Power | 1-phase 115/230 VAC, 50/60HZ |

| Barcode Scanner | Dynamic Scanning |

| Barcode Type | 1-Dimension or 2-Dimension |

| Barcode Direction | Parallel or Vertical |

| Barcode Position | Top or side surface(3 or 5 sides scanning could be customized) |

| Interface Options | RS 485/232, Ethernet |

| Loading Weight | 0.1kg~50kg |

| Accuracy | Weight: ±50g; Dimension: ±10mm |

| Parcel Dimensions | 100mmx100mmx50mm~1200mmx800mmx800mm |

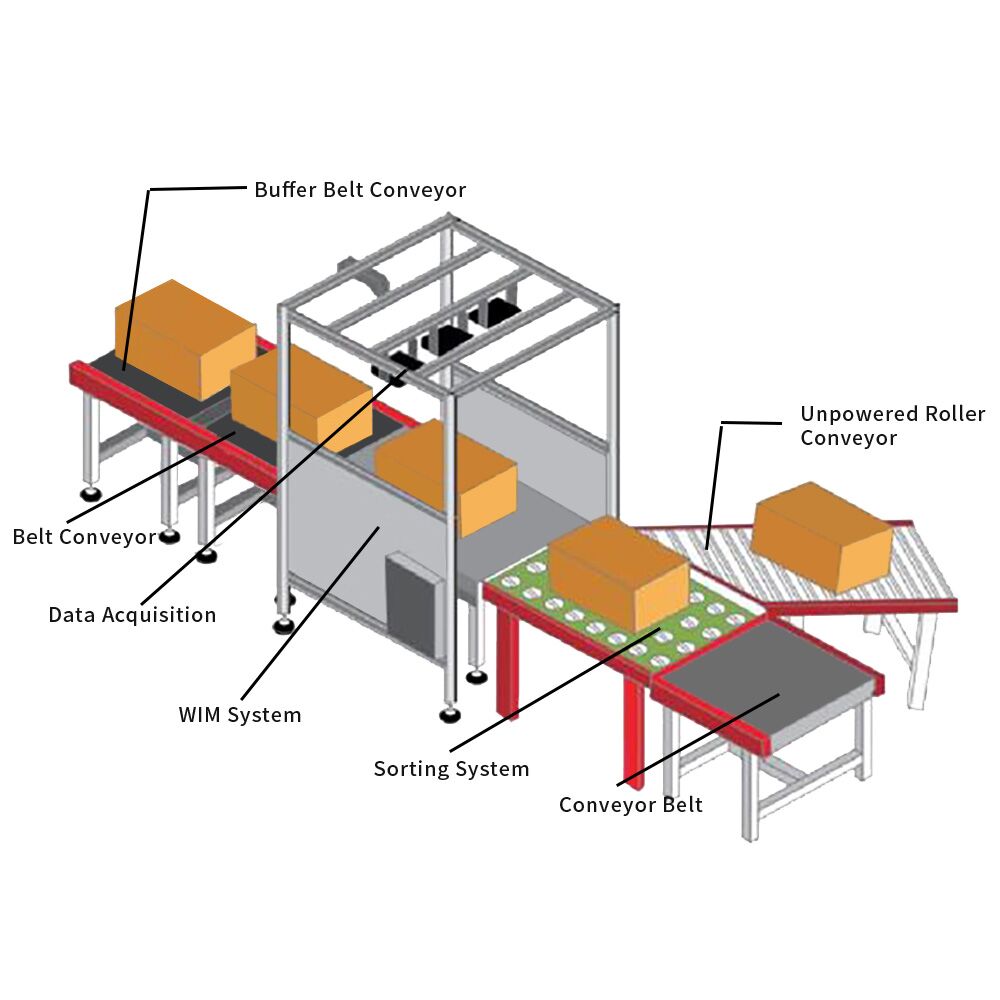

DWS system is located between the conveyor machine and sorting line, to measure the weight and dimension, and scans the bar-code automatically, then the software will upload the data information to e-commerce, courier, logistics, warehouse management, and system, etc. in real-time.

- DWS can work with a high-speed Conveyor System, the weight, volume, and barcode information can be read accurately when the conveyor belt speeds at 1.2-1.5m/s.

- DWS could achieve high efficiency to a max of 3600 parcels/hour, measuring weight, volume, and reading barcode when the parcel is moving on the machine, the data will be uploaded to the system in real-time.

- The data collected by DWS can be directly used in the management system and could support multiple customized data transfer modes.

- The alarm will ring and the conveyor will stop if abnormal conditions such as miss reading/measuring.

- The DWS system uses a module design concept. Can meet the various needs of customers, and provide a variety of application methods. To facilitate customer Integration into the existing assembly line.