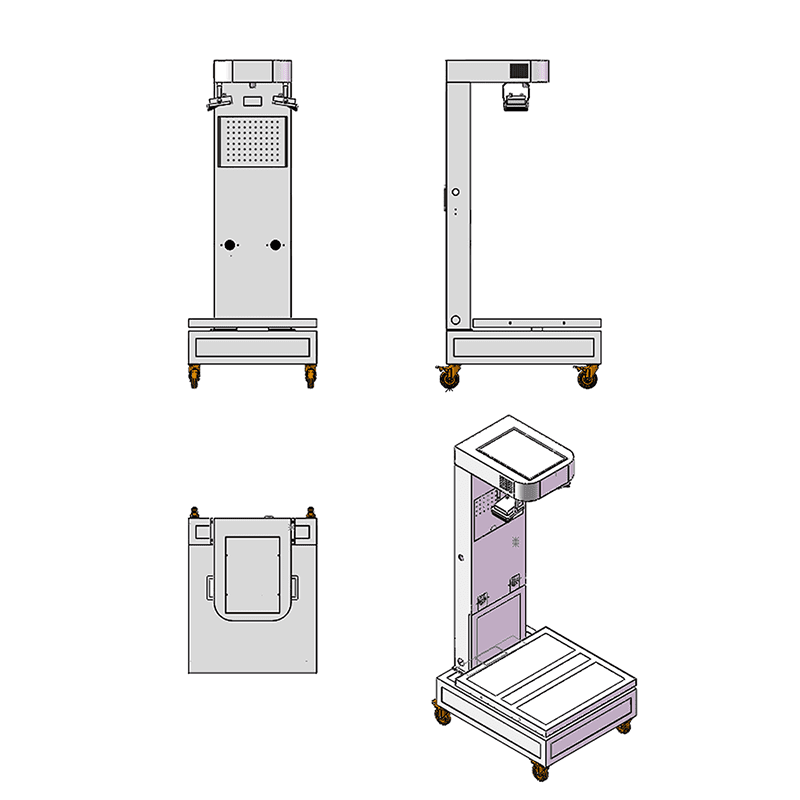

Automatic Dimensioning Machine

Widely used in Logistics, Warehouses, E-commerce, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plants, Food and beverage Factory, Farms, Retail, Food Shops, and Express industries.

NEWS & EVENTS

- Tel: 0086 173 1754 7809

- Email: info@smartconvey.com

- Mon-Fri 9:00AM - 7:00PM

Advantages:

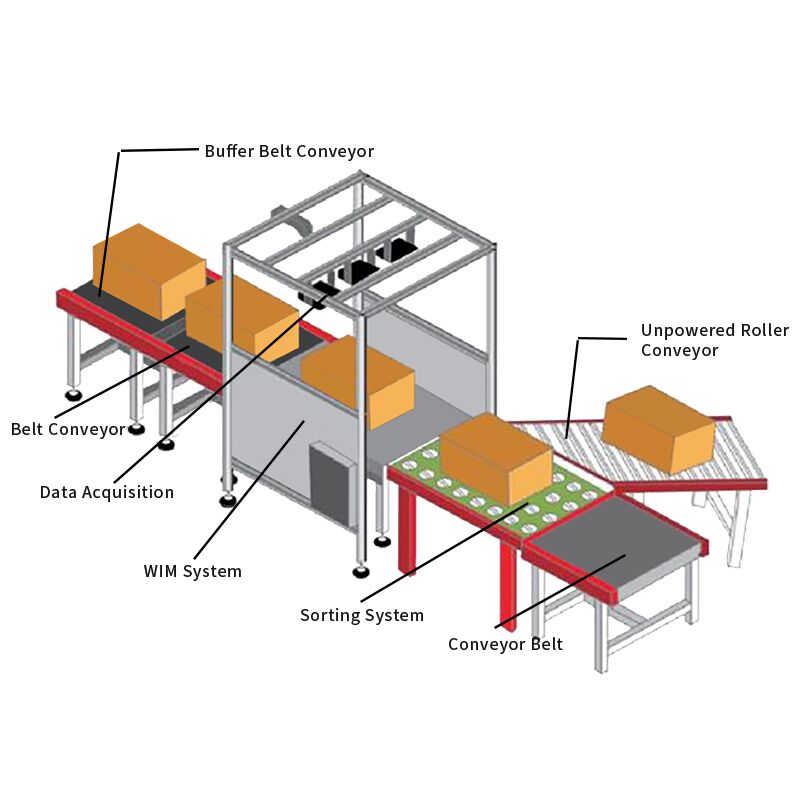

- DWS can work with a high-speed Conveyor System.

- DWS could achieve high efficiency to a max of 3600 parcels/hour.

- The data can be directly used in the management system.

- Support multiple and customized data transfer modes.

- The modular design concept provides a variety of application methods.

| Basic Dimensions | |

| Model No. | Dimension(L*W*H) |

| SC-400DWS | 1.0m/1.2m/1.4mx600mmx800mm |

| SC-500DWS | 1.0m/1.2m/1.4mx700mmx800mm |

| SC-600DWS | 1.0m/1.2m/1.4mx800mmx800mm |

| SC-700DWS | 1.0m/1.2m/1.4mx900mmx800mm |

| SC-800DWS | 1.0m/1.2m/1.4mx1000mmx800mm |

| SC-900DWS | 1.0m/1.2m/1.4mx1100mmx800mm |

| SC-1000DWS | 1.0m/1.2m/1.4mx1200mmx800mm |

| Remark: Other dimensions could be customized | |

| Basic Information | |

| Capability | Up to 3600 pieces per hour |

| Conveying Speed | 72~90 m/min(Adjustable) |

| Power | 1-phase 115/230 VAC, 50/60HZ |

| Barcode Scanner | Dynamic Scanning |

| Barcode Type | 1-Dimension or 2-Dimension |

| Barcode Direction | Parallel or Vertical |

| Barcode Position | Top or side surface(3 or 5 sides scanning could be customized) |

| Interface Options | RS 485/232, Ethernet |

| Loading Weight | 0.1kg~50kg |

| Accuracy | Weight: ±50g; Dimension: ±10mm |

| Parcel Dimensions | 100mmx100mmx50mm~1200mmx800mmx800mm |

Automatic Dimensioning Machine E-commerce Package Code Vision Scanning DWS System

DWS System Automatic Dimensioning Machine is located between the conveyor machine and sorting line, to measure the weight, and dimension, and scan the bar code automatically, then the software will upload the data information to e-commerce, courier, logistics, warehouse management, and system, etc. in real-time. It could help clients solve one-time weighing, volume measurement, barcode recognition, manual input, camera archiving, and other five basic functions.

- DWS can work with a high-speed Conveyor System, the weight, volume, and barcode information can be read accurately when the conveyor belt speeds at 1.2-1.5m/s.

- DWS could achieve high efficiency to a max of 3600 parcels/hour, measuring weight, volume, and reading barcode when the parcel is moving on the machine, the data will be uploaded to the system in real-time.

- The data collected by DWS can be directly used in the management system and could support multiple and customized data transfer modes.

- The alarm will ring and the conveyor will stop if abnormal conditions such as miss reading/measuring.

- The DWS system uses a modular design concept. Can meet the various needs of customers, and provide a variety of application methods. To facilitate customer Integration into the existing assembly line.