Logistics Sorting Conveyor System

Product Description:

Applications:

Product Description:

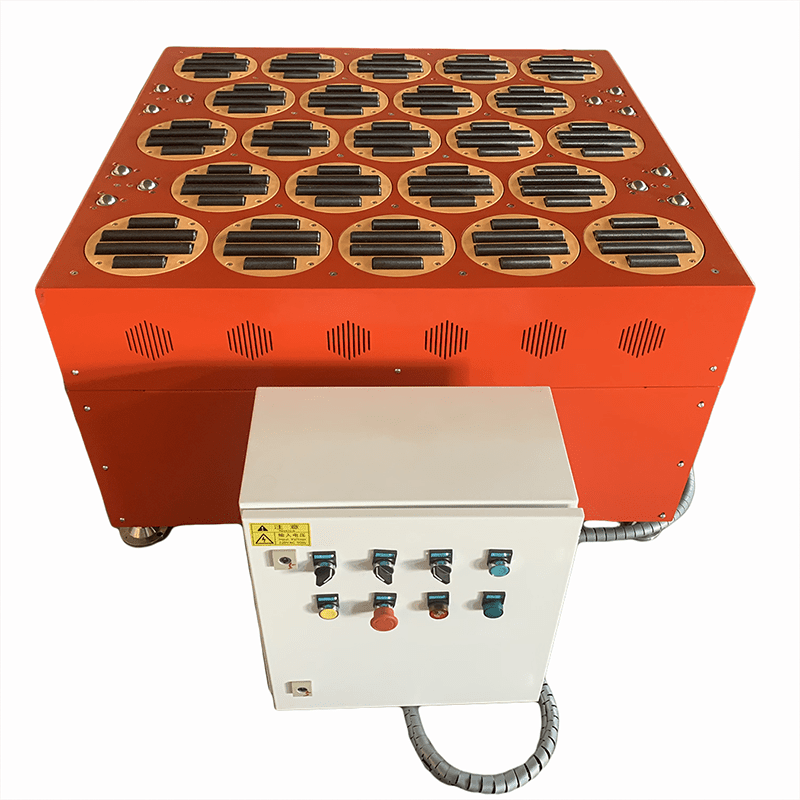

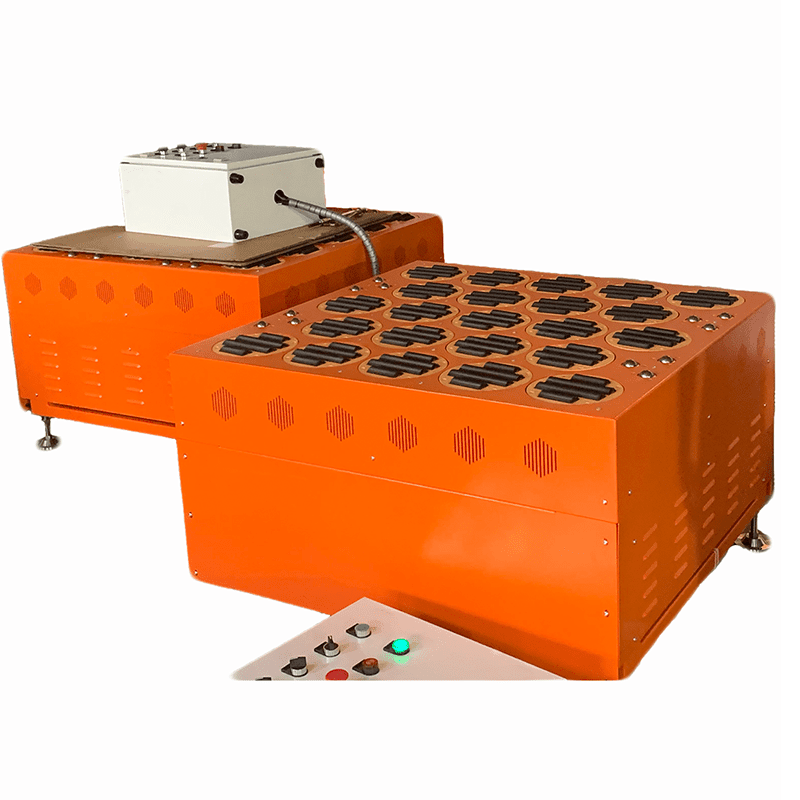

The electrical Friction Wheel Sorter is mainly designed for sorting goods according to specific standards and instructions of customers. It consists of sorting wheels, a synchronous transmission controller, a transmission device, a rack, etc.

Applications:

Widely used in Logistics, Warehouses, E-commerce, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plants, Food and beverage Factory, Farms, Retail, Food Shops, and Express industries.

NEWS & EVENTS

- Tel: 0086 173 1754 7809

- Email: info@smartconvey.com

- Mon-Fri 9:00AM - 7:00PM

Advantages:

- High Sorting Speed

- High Sorting Accuracy

- Low Noise

- Energy Conservation and Environmental Protection

- Flexible and Stable Sorting Operation

- Easy for layout and maintenance

| Basic Information | |

| Model | Electrical Friction Wheel Sorter |

| Frame Material | Carbon Steel Coated |

| Color | Orange/Blue/Black/Gray/White/Customized |

| Dimensions(L*W*H) | SC-600EFS: 621*680*800mm |

| SC-C324EFS: 814*680*800mm | |

| SC-800EFS: 814*880*800mm | |

| SC-C435EFS: 1030*880*800mm | |

| SC-1000EFS: 1030*1080*800mm | |

| SC-C546EFS: 1200*1080*800mm | |

| SC-1200EFS: 1200*1280*800mm | |

| Performance | |

| Conveying Speed | 60~120m/min(Adjustable) |

| Sorting Capacity | 7200pcs/hour(Max) |

| Diverting Angle | 30~90 Degree |

| Discharge Direction | Right, Left and Forward |

| Operating Temperature | -10~40℃ |

| Electrical | 1-phase 115/230VAC, 50/60HZ |

| Interface Options | RS485/232, Ethernet, IO |

| Max Loading Weight | 70kg/㎡ |

| Noise | Less than 75dB |

High-Efficiency DWS Parcel Sorting Machine Sorter Conveyor for Logistics Sorting Conveyor System

The sorting Conveyor System could help customers achieve maximum sorting rate and, at the same time get the best economical efficiency. Wheel sorter is most commonly used in logistics, e-commerce, and other related industries including the sorting process.

- High Sorting Speed

- Every wheel has a separate powered electrical roller

- Bidirectional sorting on both sides

- Polyurethane-coated wheels provide enough drive to minimize the loss in speed during divert

- Maximum sorting rate can reach 7200pcs/hour

- High Sorting Accuracy

- Sorting Accuracy could reach as high as 99%

- Low Noise

- Use noise elimination technology, make the noise less than 75dB

- Energy Conservation and Environmental Protection

- Use lightweight material and low energy consumption design

- Flexible and Stable Sorting Operation

- Online multi-row swivel wheel technology prevents conveying goods from vibration and damage

- Stably and flexibly sort goods from light duty to a maximum 50kg heavy duty range

- Easy for layout and maintenance

- Use modular unit design and embedding combination structure

- Sorting Exits could be placed at any position along both sides of the conveyor line