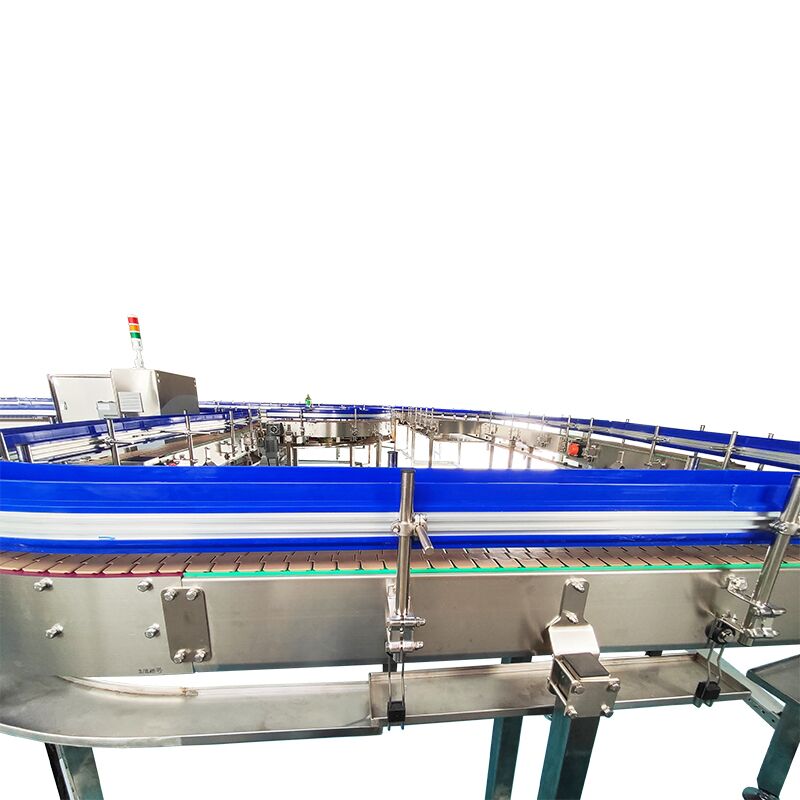

PET Bottles Filling Conveyor System

The PET bottle filling conveyor system is versatile and suitable for various industries, including beverages (carbonated drinks, juices, water, tea), food (seasonings, edible oils), pharmaceuticals (oral liquids, medicines), and daily chemicals (cosmetics, detergents), ensuring efficient and automated transportation, labeling, and packaging across diverse product lines.

NEWS & EVENTS

- Tel: 0086 173 1754 7809

- Email: info@smartconvey.com

- Mon-Fri 9:00AM - 7:00PM

Advantages:

-

Highly Efficient Automation

Stepless speed control for seamless adjustment to varying production needs. -

Stable & Reliable Performance

Anti-bottle-tipping design ensures smooth and steady bottle transport. -

Intelligent Control System

Automated monitoring and quick response with photoelectric sensors and PLC. -

Hygienic & Clean Design

Meets food-grade standards with CIP for efficient in-line cleaning.

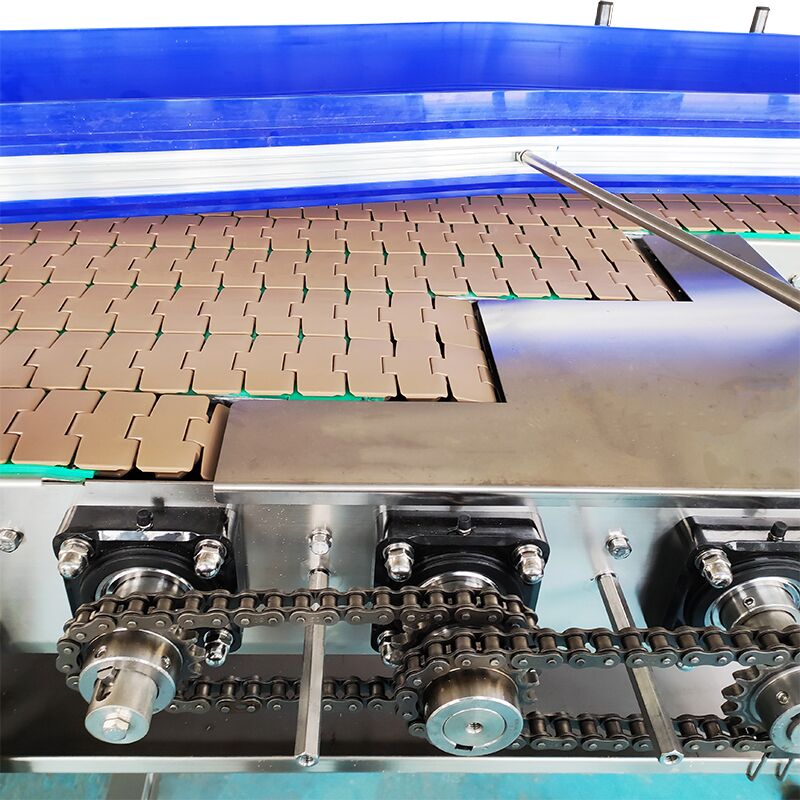

| Chain Conveyor | Details |

| Chain Type | Table Top Chain, 880TAB-K325 |

| Chain Details | Width 82.6mm, material POM |

| Speed | 0 – 45m/min(adjustable by inverter) |

| Frame Material | Stainless Steel 304 |

| Bearing Material | Stainless Steel 304 |

| Motor | China brand, 380V, 50HZ, 3 – phase |

| Frequency Inverter | Siemens brand |

| PLC | Siemens brand |

| Electrical Control | With a large overall electrical control cabinet and a PLC control panel (the PLC control panel includes the switches of each motor on each conveyor, speed parameters, alarm list, and I/O monitor). |

| Drainage Tray | Each conveyor line is equipped with a stainless steel 304 drainage tray underneath. |

| Lubrication System | All equipment is required to be equipped with a dry lubrication system. |

It is also applicable to the transportation of glass bottles or other rigid containers. The system adopts advanced automation technology to ensure efficient and stable bottle transportation, meeting the requirements of modern beverage production lines.