The material handling industry has witnessed significant advancements in recent years, and one technology that has truly revolutionized the way goods are moved is the telescopic belt conveyor. With their extendable lengths and ability to load and unload goods safely and efficiently, telescopic belt conveyors have become indispensable in various sectors such as logistics, ports, docks, stations, airports, and warehouses. They find applications in industries ranging from post and home appliances to food, tobacco, and light industry. In this article, we will delve into the versatility and efficiency of telescopic belt conveyors, exploring their different types, benefits, applications, and advancements.

Types of Telescopic Belt Conveyors

Fixed Telescopic Belt Conveyors: Streamlining Warehouse Operations

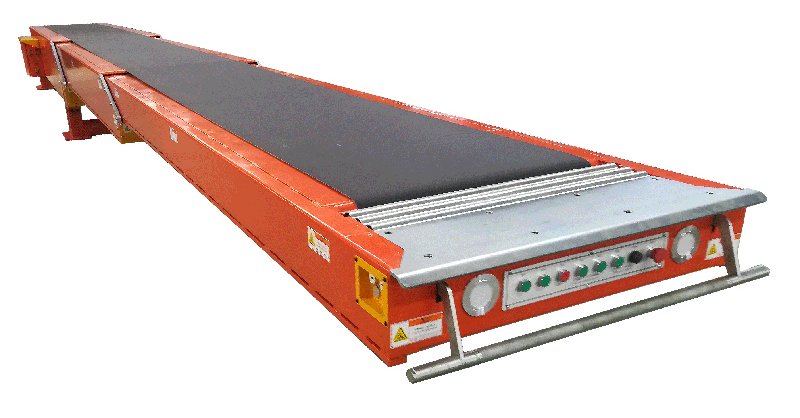

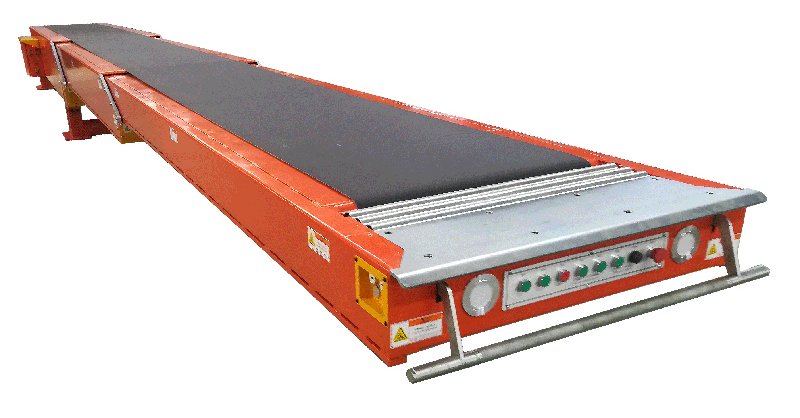

Fixed telescopic belt conveyors are designed to optimize loading and unloading processes within warehouses. They consist of a stationary base with a telescoping conveyor belt that extends as needed. The main advantage of fixed telescopic belt conveyors lies in their ability to efficiently handle the movement of goods in a controlled and streamlined manner. By eliminating the need for manual labor-intensive processes, they significantly reduce the time and effort required for loading and unloading operations.

Fixed telescopic belt conveyors have found wide application in logistics hubs, distribution centers, and warehouses. These conveyors are particularly useful when dealing with large volumes of goods, allowing for faster and more efficient material handling. By automating the loading and unloading processes, they also enhance overall productivity and reduce the risk of human error.

Mobile Telescopic Belt Conveyors: Enhancing Ergonomics and Flexibility

Mobile telescopic belt conveyors offer additional advantages over their fixed counterparts. These conveyors are designed to be easily movable and adaptable, providing ergonomic operating conditions for operators. With the ability to move in any direction, they can reach the desired positions specified by the customers, making them highly flexible in dynamic work environments.

By operating a control handle, the operator can effortlessly move the equipment in the desired direction. The telescopic movement of the conveyor can be controlled using buttons, allowing the operator to extend or retract the conveyor to the required length for loading or unloading goods. The use of motor-driven technology ensures quick feedback to the operator, making the process smooth and efficient.

Applications of Telescopic Belt Conveyors

Telescopic belt conveyors have a wide range of applications across various industries, transforming material handling processes and improving operational efficiency. Let’s explore some key sectors where these conveyors have made a significant impact:

Logistics: Efficient Movement of Goods in Distribution Centers

In the fast-paced world of logistics and supply chain management, timely and efficient movement of goods is crucial. Telescopic belt conveyors play a vital role in streamlining operations in distribution centers. With their extendable lengths, these conveyors can reach deep into trailers or containers, allowing for efficient loading and unloading of goods. By minimizing the time required for these tasks, telescopic belt conveyors contribute to faster turnaround times, reducing overall transit times and improving customer satisfaction.

Airports and Stations: Streamlining Baggage Handling Processes

The transportation industry, particularly airports and train stations, relies heavily on the smooth handling of baggage. Telescopic belt conveyors have become indispensable in these environments, where they facilitate the quick and efficient movement of luggage. These conveyors enable baggage handlers to load and unload bags directly from the aircraft or train compartments, eliminating the need for manual lifting and reducing the risk of damage or injury. The extendable feature of telescopic belt conveyors ensures that baggage can be easily accessed even in tight spaces, optimizing the use of available infrastructure.

Warehousing: Enhancing Efficiency in Storage and Retrieval

Efficient storage and retrieval of goods are vital for warehouses, where inventory management and order fulfillment are the top priorities. Telescopic belt conveyors offer a significant advantage in these settings. With their extendable lengths, these conveyors can reach deep into racks or shelves, enabling easy loading and unloading of goods. This feature streamlines the picking and packing processes, reducing the time and effort required to retrieve or store items. By enhancing overall efficiency, telescopic belt conveyors contribute to improved order accuracy, reduced inventory holding costs, and faster order fulfillment.

Advancements in Telescopic Belt Conveyor Technology

Telescopic belt conveyor technology has witnessed significant advancements in recent years, driven by the need for improved efficiency, safety, and integration with other automated systems. Let’s explore some of the notable advancements in this field:

Innovations in Motor-Driven Movement Control

Motor-driven movement control is a key area of innovation in telescopic belt conveyor technology. Advanced control systems enable precise and smooth extension and retraction of the conveyor, allowing operators to position it accurately for loading or unloading. These systems often incorporate feedback mechanisms that provide real-time information about the position and status of the conveyor. By integrating sensors and automation, motor-driven movement control enhances the overall operational efficiency and safety of telescopic belt conveyors.

Integration of Automation and IoT Capabilities

The rise of Industry 4.0 and the Internet of Things (IoT) has paved the way for the integration of automation and IoT capabilities in telescopic belt conveyors. By connecting these conveyors to central control systems, operators can monitor and manage multiple conveyors simultaneously. Real-time data, such as conveyor status, performance metrics, and maintenance requirements, can be accessed remotely, enabling proactive maintenance and optimizing operational efficiency. The integration of automation and IoT capabilities also allows for seamless integration with other automated systems within the material handling ecosystem, creating a unified and efficient workflow.

Improvements in Safety Features and Load Capacity

Safety is of paramount importance in material handling operations, and telescopic belt conveyors have seen notable improvements in safety features. These conveyors are equipped with various safety mechanisms, such as emergency stop buttons, safety interlocks, and protective guarding, to ensure the well-being of operators and prevent accidents. Load capacity has also been improved to accommodate heavier and larger items, allowing for efficient handling of a wide range of goods. These advancements in safety and load capacity further enhance the versatility and efficiency of telescopic belt conveyors, making them suitable for diverse applications.

FAQs

Q: What are the primary advantages of telescopic belt conveyors?

Telescopic belt conveyors offer several advantages, including efficient loading and unloading of goods, streamlined material handling processes, improved operational efficiency, reduced labor requirements, and enhanced workplace safety.

Q: How do telescopic belt conveyors enhance ergonomics for operators?

Mobile telescopic belt conveyors provide ergonomic operating conditions for operators. The overall movement of the equipment can be controlled using a handle, allowing operators to easily position it according to their requirements. The telescopic movement of the conveyor is controlled by buttons, making loading and unloading tasks more accessible and efficient.

Q: Which industries can benefit from telescopic belt conveyors?

Telescopic belt conveyors find applications in various industries, including logistics, ports, docks, stations, airports, and warehouses. They are particularly useful in the post, home appliances, food, tobacco, steel drums, and light industry sectors.

Q: How do telescopic belt conveyors contribute to warehouse efficiency?

Telescopic belt conveyors streamline warehouse operations by optimizing the loading and unloading processes. They eliminate the need for manual labor-intensive tasks, reduce time and effort, and enhance overall productivity. With their extendable lengths, these conveyors efficiently handle the movement of goods, leading to faster turnaround times and improved operational efficiency.

Q: Are telescopic belt conveyors compatible with automation and IoT technologies?

Yes, telescopic belt conveyors can be integrated with automation and IoT technologies. By connecting these conveyors to central control systems, operators can monitor and manage them remotely. Real-time data on conveyor status, performance, and maintenance requirements can be accessed, enabling proactive maintenance and optimizing operational efficiency.

Q: What safety features do telescopic belt conveyors have?

Telescopic belt conveyors are equipped with various safety features, including emergency stop buttons, safety interlocks, and protective guarding, such as a bumper bar at the front end. And in the process of extending, if there is someone in front, the telescopic boom will immediately sense and stop immediately. These features ensure the well-being of operators and prevent accidents during the loading and unloading processes.

Conclusion

Telescopic belt conveyors have transformed material handling operations across industries, revolutionizing the way goods are loaded, unloaded, and moved. With their versatility and efficiency, these conveyors streamline warehouse operations, enhance ergonomics for operators, and contribute to overall productivity and safety. Advancements in technology, such as motor-driven movement control, automation, and IoT integration, have further improved the capabilities of telescopic belt conveyors. As the material handling industry continues to evolve, telescopic belt conveyors will remain a key component in achieving efficient and effective material flow, ensuring the smooth movement of goods in various sectors.