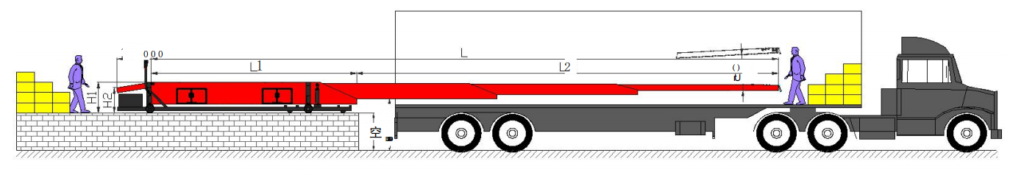

A telescopic belt conveyor, also called a telescopic loading conveyor, is an essential tool for safe and effective truck loading and unloading. It can freely expand and retract in the length direction, and control the length of the conveyor at any time.

It can transport materials in two directions and can be used in conjunction with other conveying equipment and material sorting systems to realize the automatic production of materials in and out of storage or truck loading and unloading, It has been widely used in various industries.

First, here comes the fixed type of telescopic belt conveyor. It helps a lot for the loading and unloading process, with its featured advantages as below:

- Easy operation: need to control by buttons to make the conveyor free extend and retract, reduce manual round-trip handling, and reduce labor intensity

- Efficient operation: based on the standard loading speed of 30 m/min, the theoretical maximum loading capacity of cartons (800*600mm) per hour could be 2250 pieces

- Standard operation: make loading and warehousing on-site standard process operations in an orderly manner, effectively avoiding the phenomenon of messy and full-floor operations on the site

- Labor saving: the number of loading labor can be reduced to more than 1/3 of the original

- Safe operation: Minimize accidents during loading

- Improve corporate image: standard automation equipment assembly line operation, meeting the requirements of modern enterprises

- Suitable for various cargo types: cartons, woven bags, parcels, luggage tires, plastic boxes, plastic drums, etc

- Rated load: 60KG/M

As fixed type is so helpful already, why does the mobile type come out?

The answer is that a telescopic belt conveyor with a large length is usually too heavy. It will be difficult and unsafe to move it to different positions by always using a forklift. A mobile-type telescopic belt conveyor is designed to solve this problem exactly.

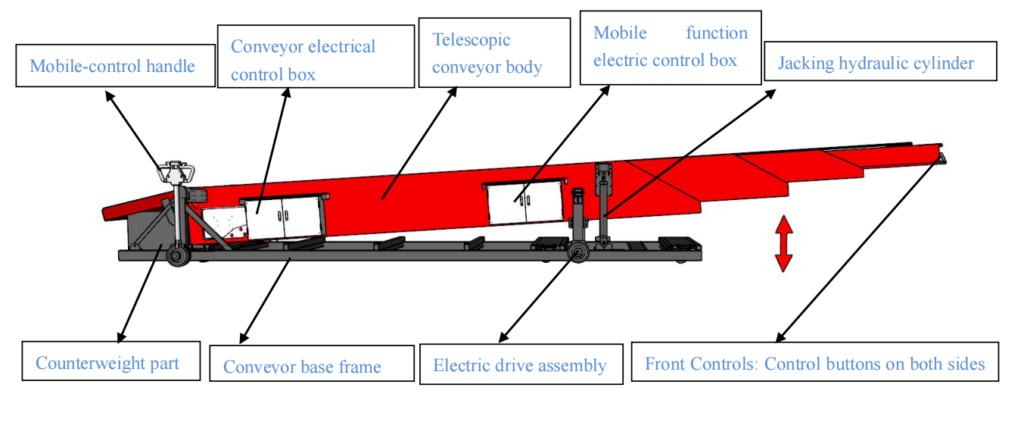

Let’s start with the structure of mobile telescopic belt conveyors:

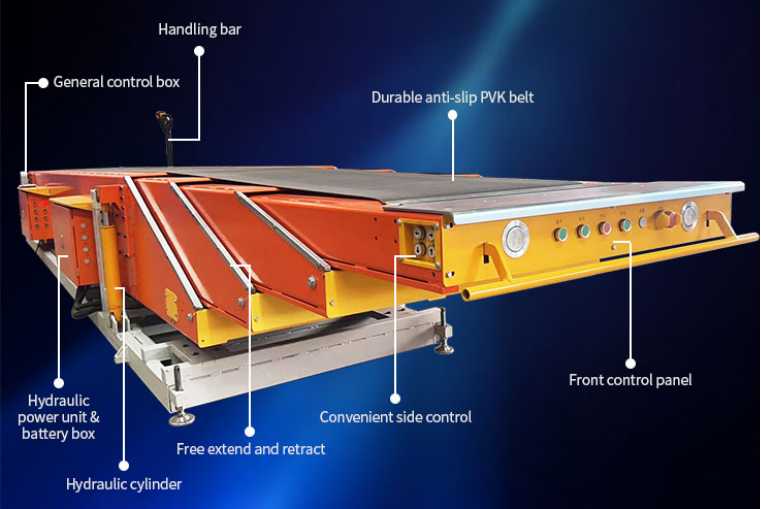

Normal common structures of fixed telescopic belt conveyors are:

- There are control panels and buttons on the front and sides of the conveyor

- The automatic sensing anti-collision device is set at the front end when someone passes by, it will automatically stop

- There is a safety warning bell ringing while the conveyor is working

- Hydraulic unit and hydraulic cylinder to adjust the height of the conveyor, to meet the elevation needs

- Two directions of the conveyor belt, forward for loading and reverse for unloading

For mobile telescopic belt conveyor, has been upgraded on the below structures:

- Add 4+2 pieces of steerable heavy-duty wheels to make the conveyor easy to move

- Handling bar to control the moving directions of the whole conveyor

- The conveyor moving power is driven by a chargeable lithium battery, a capacity of 56Ah

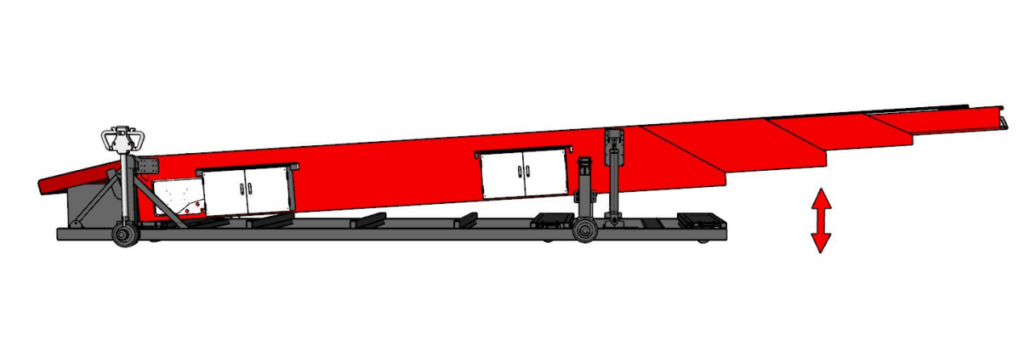

- The hydraulic cylinder design makes the conveyor height to be adjustable up and down

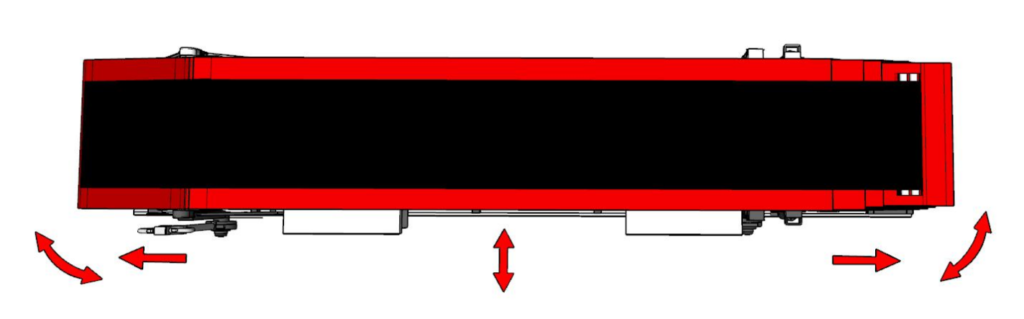

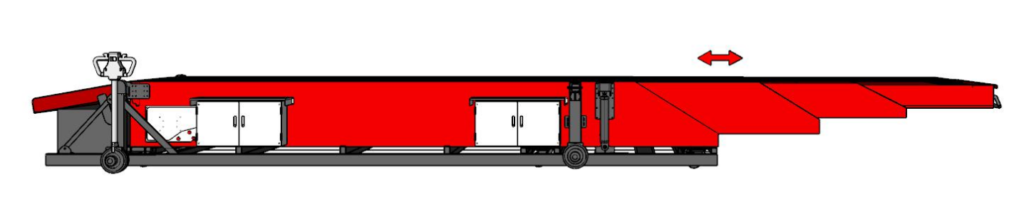

Let’s see how many directions the mobile telescopic belt conveyor can move and how it works:

The conveyor can move horizontally, front and rear, left and right, and can also rotate in any direction. The overall movement is powered by the battery.

After the conveyor moves to the designated position, it can be connected to an external required industrial power to realize free telescopic movement and reach the designated loading and unloading position.

The whole conveyor can realize the lifting movement through the hydraulic jacking mechanism, which reduces the labor intensity of loading and unloading.

In conclusion, mobile telescopic belt conveyors only need 1 person to move it easily by handling the bar. If there are 2 or more doorways, the operator could operate the handling bar to make the wheels run front and rear, right and left, and rotate 360°freely, to move the conveyor sideways from one doorway to another one. Compared with a lot of sets of fixed type, one set of mobile type could be much more cost-saving.

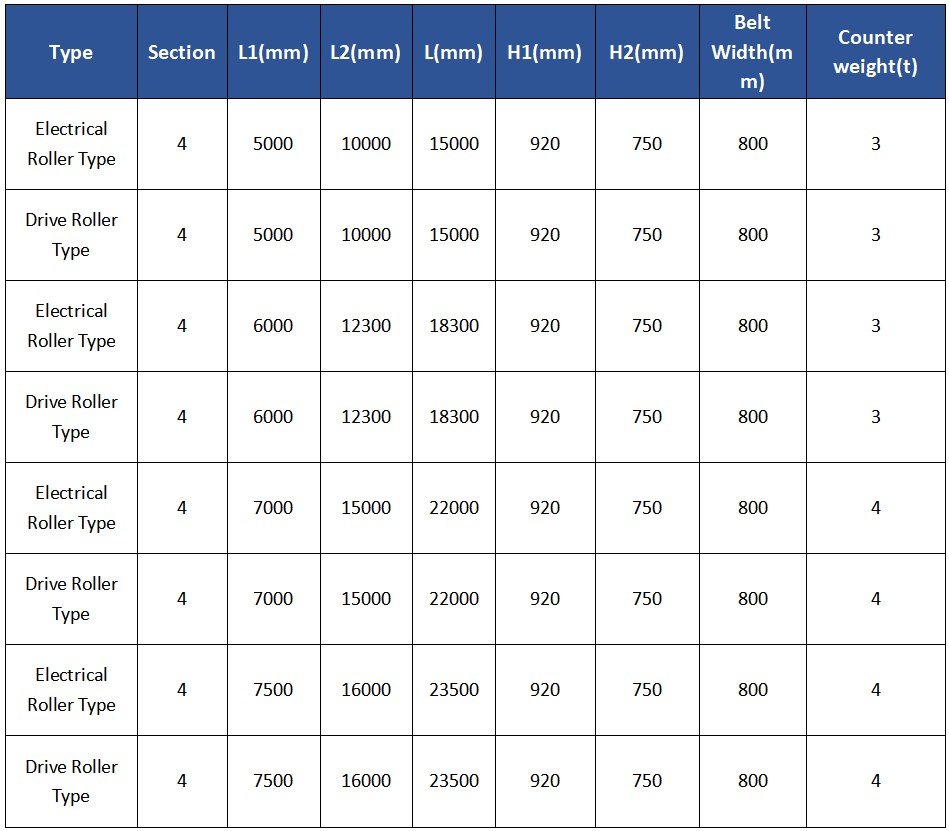

If need to choose a mobile telescopic belt conveyor, what are the available dimensions?

These are just the common dimensions, for customized requirements, could feel free to contact us at www.smartconvey.com, or email info@smartconvey.com, to get your own customized solution.