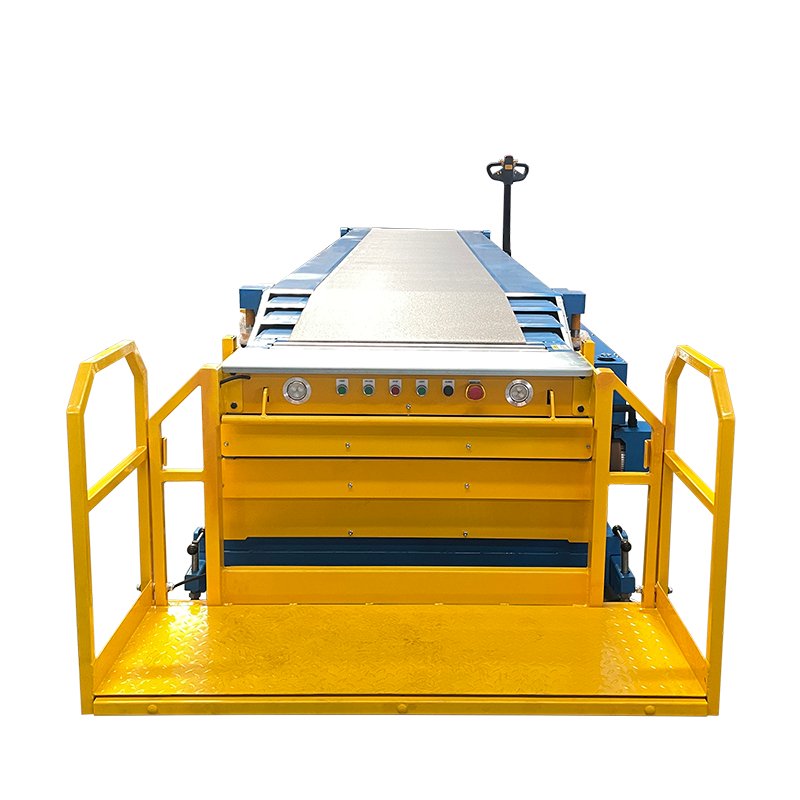

Discover the meticulous precautions and operational insights vital for the effective use of the Telescopic Belt Conveyor. This article provides a comprehensive overview of the critical considerations before, during, and after the operation, covering aspects such as equipment inspection, safe handling practices, and prohibited items. Ensure a seamless workflow and prevent potential hazards by incorporating these guidelines into your conveyor system management.

Precautions Before Operation:

- 1) Check for any foreign objects or personnel in non-safe positions during startup.

- 2) Ensure the operating voltage matches the rated voltage, and if it exceeds 10% of the rated voltage, stop the operation.

- 3) Inspect for loose bolts and nuts, as well as the inclination of the support frame.

Precautions During Use:

- 1) Exercise caution when placing goods on the conveyor to prevent equipment damage from the impact of heavy items.

- 2) Assign dedicated personnel to monitor the equipment during operation. If personnel are away from the site for an extended period, shut down the conveyor.

- 3) The equipment requires approximately 20 seconds for normal startup. If a stop is necessary, press the stop button after 20 seconds of startup.

- 4) After the equipment stops, do not leave items stacked on the conveyor surface for an extended period.

Prohibited Items for Conveyance:

- 1) Items with a width exceeding 1200mm.

- 2) Single items weighing more than 80kg.

- 3) Goods are packaged in wooden boxes or other external packaging with nails (metal packaging) or sharp edges, such as blades.

- 4) Goods packaged on pallets.

- 5) Goods wrapped in foam plastic.

- 6) Non-standard or damaged packaging.

- 7) Fragile materials or flammable liquid items.

- 8) Unstable (cylindrical, spherical) objects.

4. Strictly Forbidden Rough Handling: Throwing or smashing objects can damage both the items and the equipment.

5. If Foreign Objects are Detected or the Conveyor Belt Tears During Operation: Immediately stop the operation, eliminate the foreign objects, and then resume operation.

6. Strict Prohibition Against Personnel Walking on the Conveyor Line, Pulling Foreign Objects into the Equipment by Hand, Touching Drum Rollers, or Making Contact with Areas Adjacent to Drum Rollers.

In conclusion, the proper operation of the Telescopic Belt Conveyor demands careful attention to pre-start checks, vigilant use during operation, and adherence to safety protocols. By avoiding prohibited items, rough handling practices, and addressing abnormalities promptly, users can enhance equipment longevity and maintain a secure working environment. Implementing these guidelines is integral to maximizing the efficiency and safety of Telescopic Belt Conveyor systems in diverse industrial settings.