In the late stage of the third industrial revolution, along with economic globalization, the development of science and technology especially the development of information technology and communication technology, as well as the emergence of multinational corporations which brought localized production and global purchasing.

Economic transformation and industrial structure upgrading started all over the world. The production capacity has achieved a leap-forward development and traditional labor-intensive sorting and conveying no longer meets the huge requirements again. At this time, an automatic Conveyor sorting system appears in people’s sight. It leads the logistics industries to update from labor-intensive to automation.

Today, the automatic sorting system has been developed by the control device as a core and consists of a sorting device, conveying device, and sorting gate. It’s famous for conveying in continuous and high capacity, sorting with a tight error rate, and smart sorting.

- Automatic warehousing conveyor: Palletized good automatic delivery and warehousing;

- Stacker: Automatic inventory, pick-up, and replenishment of palletized goods, with a running speed of 180 m/min;

- Stereoscopic warehouse: Automatic restocking, automatic delivery after picking up goods;

- Automatic sorting system: Automatic supplying, sorting capacity exceeds 20,000 pieces/hour, sorting accuracy rate exceeds 99.99%.

It’s unbelievable to have such high efficiency and automation!

Automatic sorting system helps factories to develop from labor-intensive to automation and saves labor costs. In the meanwhile, the factory got high efficiency to become more competitive in the market.

But how do choose optimal equipment?

Before the question, we should know its working parts.

Automatic Warehousing Conveyor

A. Flexible Roller Conveyor

Flexible Roller Conveyor, equipment is composed of motors, electric control boxes, foot pulleys, driving rollers, aluminum side plates, film racks, tie rods, bearings, driving devices, and O-belts.

Features:

- High capacity and speed, easy to handle and maintain;

- Standard dimension, competitive cost, fast delivery time;

- Suitable for any kind of factory with different dimensions.

B. Gravity Roller Conveyor

Roller Conveyor is composed of motors, electric control boxes, foot pulleys, driving rollers, side plates, film racks, tie rods, bearings, driving devices, and roller chains.

Features:

- High capacity and speed, easy to handle and maintain;

- Standard and customized dimension, fast delivery time;

- Suitable for heavy-duty conveying like bags, cases, boxes, pallets, and any other heavy-duty cargo.

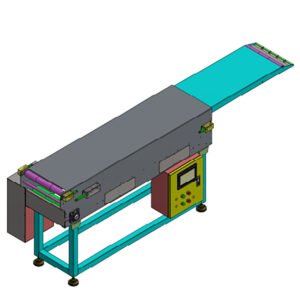

C. Telescopic Conveyor

Telescopic Conveyor is composed of motors, conveyor belts, idlers and frames, transmissions, tensioning devices, storage devices, and braking devices. Popularly used for loading and unloading at ports, wharves, stations, airports, warehouses, mines, post and telecommunications, electrical appliances, light industry etc.

Features:

- Reduce loading and uploading time;

- Standard and customized dimension, fast delivery time;

- Suitable for light conveying like bags, cases, boxes, and unpacked goods;

- Emergency stop and safety device;

- Automatic and programmatic operation.

Automatic Sorting System

A. Electrical Friction Wheel Sorter

Simple construction design, reliable operation, and no need for frequent maintenance. Independently controlled, the sorting action can be achieved by simply receiving a signal, greatly reducing the time required for on-site commissioning. The sorter uses servo motors and sensing and detection of the pendulum movement, interlocked with the sensor signal, for fast action response and stable and reliable sorting. The sorting steering mechanism is linked by spherical bearings. The sorting angle can be fine-tuned, allowing for more flexibility in on-site commissioning. The equipment is equipped with adjustable feet, which can now be flexibly adjusted to the actual situation. Learn more

Features:

- With easy layout and maintenance with the modular design of the units and the embedded combination structure, sorting outlets can be placed anywhere on both sides of the conveyor line.

- Flexible and stable sorting operation in-line multi-row gimbal technology prevents vibration and damage to the goods being conveyed. Stable and flexible sorting of goods from light loads to heavy loads of up to 70 kg.

- Customizable The angle rotation is powered by servo motors and has a resolution of less than 1 degree for custom angles from 0 to 90 degrees. Suitable for high throughput and large parcels.

- High resolution Each wheel is an independent power unit, designed specifically for tell-tale sorting, which can be carried out simultaneously in both directions. Polyurethane bail rollers provide sufficient drive power to minimize speed loss during sorting.

- Low noise new environmentally friendly materials and noise reduction technology, with a noise level as low as 75dB

- Energy-saving lightweight materials and low energy consumption design construction

B. Electrical Wheel Sorter

Simple structural design, reliable movement, and no need for frequent maintenance. Rocker arm with servo motor, fast response time, stable and reliable. Compact structure and smooth sorting. Independently controlled, the sorting action can be realized by simply accepting the sorting signal, greatly reducing commissioning time on site. The sorter uses a servo motor with sensors to detect the movement of the balance wheel and link it to the sensor signals to ensure the stability and reliability of the sorting. The sorting steering mechanism is connected by spherical bearings. Learn more

The sorting angel can be fine-tuned, making on-site commissioning more flexible. The equipment is equipped with adjustable feet, which can now be flexibly adjusted to the actual situation

Features:

- High Sorting Rate Designed for high-speed sorting operation on both sides at the same time. The maximum Sorting package can reach 7200 pieces/hour.

- Low Noise Using new material and noise elimination technology good for the environment, noise can be less than 75 DB.

- Energy Conservation and Environmental Protection Lightweight material, low energy consumption structure, low power, and source power (conveyor) drive to achieve successful operation.

- Flexible and Stable Sorting Operation With online double-row swivel wheel technology, it prevents conveyed goods from vibration and damage stably and flexibly, weighing from lightweight to a maximum of 50kg package.

- Easy Layout and Maintenance Counting on unit modular design and embedding combination structure, it is easy for sorting positions to be placed at any point along both sides of a conveyor line. The product is more reasonably, simply, conveniently used, and maintained.

C. O-belt Wheel Sorter

Used in belt conveyor systems or roller conveyor systems, the design features accurate, stable tracking of the goods being conveyed and the ease of setting up picking positions at any point on either side of the conveyor line to suit customers with different sorting requirements. Maximum sorting efficiency and optimum economic efficiency are achieved at the same time. Learn more

Features:

- Durable one-piece molding without any contact ensures a longer service life.

- High sorting rate the switch to height and bi-directional design allows sorting on both sides at the same time. The maximum sorting speed can be 7200 pieces/hour (theoretical value)

- Low noise new environmentally friendly materials and noise reduction technology, noise level as low as 75dB

- Energy-saving Lightweight materials and low energy consumption design construction and low power (conveyor belt) allow for successful drives

- Flexible and stable sorting operation in-line multi-tap gimbal technology prevents vibration and damage to loose goods. Stable and flexible sorting of goods in the range of light loads to heavy loads of up to 30 kg.

- With easy layout and maintenance with the modular design of the units and the embedded combination structure, the sorting outlets can be placed anywhere on both sides of the conveyor line.

From the above information, we believe you’ve had an idea to choose the optimal equipment for your factory. Generally, automatic logistics is acceptable and chosen by more and more modern factories as a way to improve capacity and promote enterprise competitiveness. The next step, we believe would be to develop toward smart and module.